news, latest-news, hydrogen, ActewAGL, refuelling station, Hyundai fuel cell car

After a long hiatus due to COVID-19 travel issues and restrictions, Canberra has now found itself in an unexpected race against the world’s largest car company to open the country’s first public hydrogen refuelling station. Toyota Australia is planning to open its solar-powered hydrogen refuelling station at Altona, the shuttered Victorian factory where it once produced the Camry. The car company is planning to launch a second generation hydrogen-powered Mirai – meaning “future” in Japanese – into Australia in April-May this year and has begun installation of its Altona refuelling plant as a key plank in promoting the alternative fuel locally prior to the start of the Tokyo Olympics. Company president Matt Callachor has also flagged that Toyota sees “very good potential” in using hydrogen as a future transport fuel for its best-selling light trucks. As a key sponsor of the Games, the Japanese car giant has invested hundreds of millions of dollars in promoting hydrogen as the fuel for the world’s “next generation” electric vehicles, and aims to spread the message around its global markets. As a transport fuel, hydrogen offers a significant advantage over battery-powered electric vehicles which plug into the grid. A hydrogen fuel cell vehicle (FCV) is essentially an electric vehicle but stores its fuel on board, with a chemical reaction to generate the electricity to power the electric motors. The only byproduct is water. The refuelling nozzles are as familiar and easy to use as a petrol station. Hydrogen cars can be refuelled quickly, have a better driving range than most plug-in electric vehicles and don’t lug around the heavy weight of a big battery pack. Power is needed from the grid to produce the gas, condense it and liquify it, but that process can be done when electricity prices – in the ACT’s case, sourced from wind and solar – are at their cheapest. The storage tanks then act like a big liquid battery. The ACT is still confident it can beat Toyota to the line as most of its key infrastructure is already installed at ActewAGL’s refuelling station in Fyshwick. ActewAGL had hoped to have the station up and running by late last year but complications due to the COVID travel restrictions have pushed the timetable back. The 20 Hyundai Nexo fuel cell electric vehicles leased from the Korean importer and sub-leased by the ACT government’s provider SG Fleet, have been delivered to Canberra. The cars, worth around $100,000 each, have been wrapped in identification so won’t go unnoticed as they drive around Canberra’s streets. ActewAGL’s Mark Smeaton, who as the company’s commercial manager of new energy has been heading up the project since its inception about 18 months ago, said that the process of commissioning and validating the Fyshwick pilot plant isn’t as simple as opening a conventional petrol station, installing bowsers and filling the tanks. “We are the first to do this in Australia so we’ve been learning as we go along, and it has been a steep learning curve,” Mr Smeaton said. “There are elements to this project which, given that members of the public will be coming and going from here and refuelling their cars, make it quite different to a privately-run refuelling station. “It will be completely safe, of course, and as user-friendly as we can possibly make it.” One key element to the project is ensuring that the hydrogen it produces is pure enough. The hydrogen has to be 99.97 per cent pure or it will potentially contaminate the car’s on-board fuel cell. “We have already turned the plant on and produced some hydrogen here, so we know all the equipment works,” he said. “After the purity test and the validation, the next step is to begin to compress and store the hydrogen on site and test the dispensing equipment.” Hydrogen is stored in a series of pressure tanks at the Fyshwick plant, with the top tank being at a maximum 700 bar pressure, or around 700 times atmospheric pressure. Even the way the hydrogen enters the car’s fuel tank is complex because to “top out” the tank, the fuel has to be progressively ramped up in pressure. The amount of fuel going in is measured in weight, not volume, with a Nexo capable of carrying just over 6kg of hydrogen on board for around 600km of driving range. The size of the Fyshwick station and the amount of hydrogen it can dispense is geared to serving the needs of the 20 vehicles under lease. It can produce around 20kg a day but easily is capable of being scaled up to 60kg, provided there was sufficient demand. “The hardest step in this project was the first one, and the ACT government deserves the accolades for taking that leap of faith, if you like,” Mr Smeaton said. “This plant we have built is currently scaled to the size of the fleet it will serve,” he said. “What’s needed to take this project to the next level as more vehicles to become available is for a larger operator, such as a transport company, to make a commitment [to the fuel]. That’s when you start to get more throughput. “As more refuelling stations start to spring up in Sydney and around the place, and manufacturers begin to produce trucks and buses, that’s when the hydrogen transport market will really gather momentum. And there is no doubt that will happen.”

/images/transform/v1/crop/frm/ZBtA3uhzm786CWHKXPpjK4/b14249ff-5e10-48ee-b07a-3b1b77a60282.jpg/r0_195_4103_2513_w1200_h678_fmax.jpg

After a long hiatus due to COVID-19 travel issues and restrictions, Canberra has now found itself in an unexpected race against the world’s largest car company to open the country’s first public hydrogen refuelling station.

Toyota Australia is planning to open its solar-powered hydrogen refuelling station at Altona, the shuttered Victorian factory where it once produced the Camry.

The car company is planning to launch a second generation hydrogen-powered Mirai – meaning “future” in Japanese – into Australia in April-May this year and has begun installation of its Altona refuelling plant as a key plank in promoting the alternative fuel locally prior to the start of the Tokyo Olympics.

Company president Matt Callachor has also flagged that Toyota sees “very good potential” in using hydrogen as a future transport fuel for its best-selling light trucks.

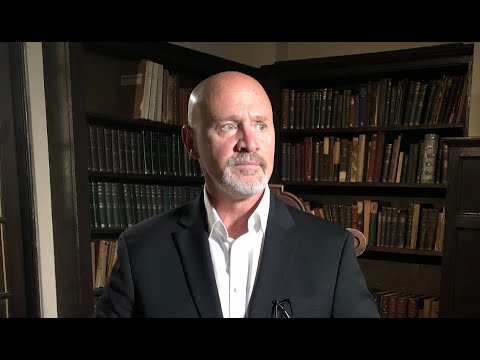

The ACT government will soon boast the biggest fleet of Hyundai Nexo fuel cell electric vehicles in the country. Picture: Peter Brewer

As a key sponsor of the Games, the Japanese car giant has invested hundreds of millions of dollars in promoting hydrogen as the fuel for the world’s “next generation” electric vehicles, and aims to spread the message around its global markets.

As a transport fuel, hydrogen offers a significant advantage over battery-powered electric vehicles which plug into the grid.

A hydrogen fuel cell vehicle (FCV) is essentially an electric vehicle but stores its fuel on board, with a chemical reaction to generate the electricity to power the electric motors. The only byproduct is water.

The refuelling nozzles are as familiar and easy to use as a petrol station. Hydrogen cars can be refuelled quickly, have a better driving range than most plug-in electric vehicles and don’t lug around the heavy weight of a big battery pack.

Power is needed from the grid to produce the gas, condense it and liquify it, but that process can be done when electricity prices – in the ACT’s case, sourced from wind and solar – are at their cheapest. The storage tanks then act like a big liquid battery.

The pressure tanks which will store the hydrogen, with the top tank at 700 bar pressure. Picture: Peter Brewer

The ACT is still confident it can beat Toyota to the line as most of its key infrastructure is already installed at ActewAGL’s refuelling station in Fyshwick.

ActewAGL had hoped to have the station up and running by late last year but complications due to the COVID travel restrictions have pushed the timetable back.

The 20 Hyundai Nexo fuel cell electric vehicles leased from the Korean importer and sub-leased by the ACT government’s provider SG Fleet, have been delivered to Canberra.

The cars, worth around $100,000 each, have been wrapped in identification so won’t go unnoticed as they drive around Canberra’s streets.

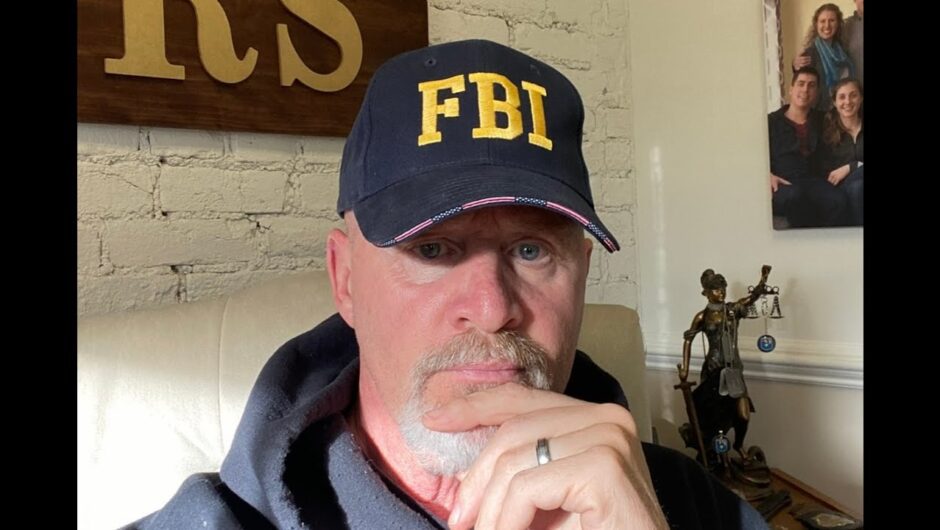

ActewAGL’s hydrogen project leader Mark Smeaton at the Fyshwick refuelling station. Picture: Peter Brewer

ActewAGL’s Mark Smeaton, who as the company’s commercial manager of new energy has been heading up the project since its inception about 18 months ago, said that the process of commissioning and validating the Fyshwick pilot plant isn’t as simple as opening a conventional petrol station, installing bowsers and filling the tanks.

“We are the first to do this in Australia so we’ve been learning as we go along, and it has been a steep learning curve,” Mr Smeaton said.

“There are elements to this project which, given that members of the public will be coming and going from here and refuelling their cars, make it quite different to a privately-run refuelling station.

“It will be completely safe, of course, and as user-friendly as we can possibly make it.”

One key element to the project is ensuring that the hydrogen it produces is pure enough. The hydrogen has to be 99.97 per cent pure or it will potentially contaminate the car’s on-board fuel cell.

“We have already turned the plant on and produced some hydrogen here, so we know all the equipment works,” he said.

“After the purity test and the validation, the next step is to begin to compress and store the hydrogen on site and test the dispensing equipment.”

The dispensing pump at Fyshwick will push chilled hydrogen into the car’s tank at up to 700 times atmospheric pressure. Picture: Peter Brewer

Hydrogen is stored in a series of pressure tanks at the Fyshwick plant, with the top tank being at a maximum 700 bar pressure, or around 700 times atmospheric pressure.

Even the way the hydrogen enters the car’s fuel tank is complex because to “top out” the tank, the fuel has to be progressively ramped up in pressure.

The amount of fuel going in is measured in weight, not volume, with a Nexo capable of carrying just over 6kg of hydrogen on board for around 600km of driving range.

The size of the Fyshwick station and the amount of hydrogen it can dispense is geared to serving the needs of the 20 vehicles under lease. It can produce around 20kg a day but easily is capable of being scaled up to 60kg, provided there was sufficient demand.

“The hardest step in this project was the first one, and the ACT government deserves the accolades for taking that leap of faith, if you like,” Mr Smeaton said.

“This plant we have built is currently scaled to the size of the fleet it will serve,” he said.

“What’s needed to take this project to the next level as more vehicles to become available is for a larger operator, such as a transport company, to make a commitment [to the fuel]. That’s when you start to get more throughput.

“As more refuelling stations start to spring up in Sydney and around the place, and manufacturers begin to produce trucks and buses, that’s when the hydrogen transport market will really gather momentum. And there is no doubt that will happen.”